Packaged Equipment

Make an Enquiry

Recent News

The G99 range from Highnett has been reduced in price.

This has been made possible by.

· Adoption of new production methods that provide greater efficiency, with less waste.

· Simplified design and manufacturing process.

· Savings from recently negotiated supplier relationships have been passed on to you the customer.

The outcome is that you will see a reduction in the price of our G99 panel range, without any loss in quality.

It goes without saying that Highnett will continue to provide you with the same great customer service and guarantees.

Contact us now on info@highnettcontrols.co.uk or calls us on 01635 231155.

A customer came to us asking if we could help repair and update their large Mobile Agricultural seed cleaner. After years of good service, the system was now failing on a regular basis and needed a complete overhaul. Being close to harvest time it may not leave sufficient time to get the job done.

Unfortunately for the customer the Company that had originally designed and built the system had since closed and the owner retired. Luckily, the customer was still in contact with the retired owner, who knew us from past dealings and suggested we were the ideal company to do the work and that he would be happy to provide further information to help us move the project along.

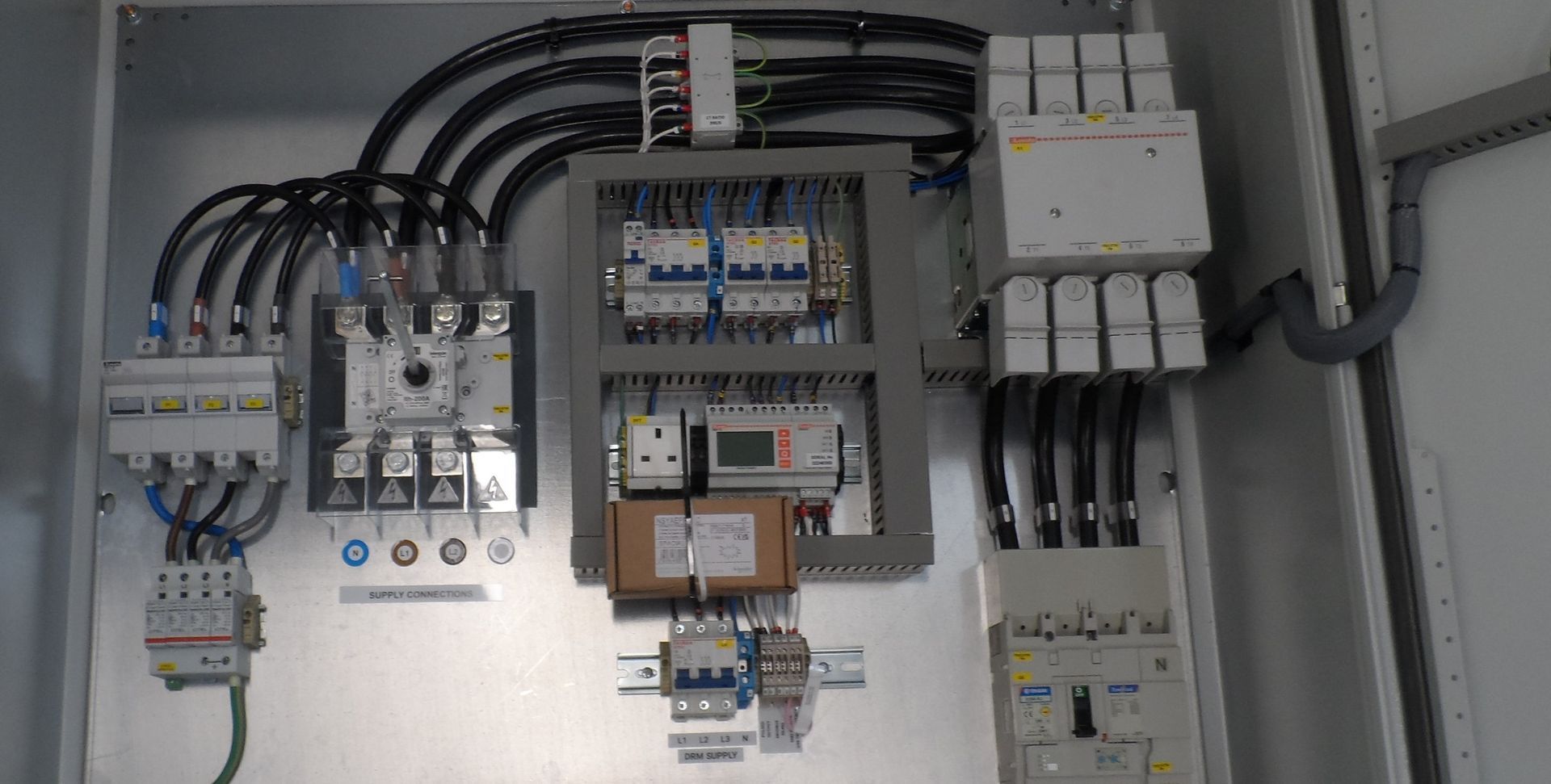

A site visit was needed to get hands -on and find out what was needed from us. After discussing the full requirement with the customer and original manufacturer, we set about producing a design to replace the existing electrical control panel with an up-to-date version that would meet all the latest requirements. Based on the original specification using Schneider switchgear and components. To be supplied fully wired and tested with all labels and Electrical schematic drawings.

The customer was happy with the price and lead time quoted and the order went ahead.

In time for us to complete the task and restore the mobile seed sorter to full function and reliability in time for harvest.

No seed left unturned.